Surface preparation

Before assembling or superficially treating metallic materials, their surface should be cleaned.

The nature of this surface preparation depending on the objective to be achieved, there are several mechanical, chemical or electrolytic treatments to consider.

Degreasing

Degreasing is an essential preparatory step for a heat treatment or surface treatment operation. The process involves removing traces of grease from another element.

To eliminate grease, it is possible to:

- dissolve them using a solvent

- transform them into water-soluble soaps, using products such as soda, potash or sodium silicates

- loosen them and prevent them from redepositing, using surfactants and thus forming an emulsion

Sanding

Sandblasting consists of stripping a surface by projecting, at high speed and under high pressure, an abrasive through a nozzle. Sandblasting makes it possible to perfectly strip, renovate, deoxidize and prepare surfaces for subsequent coatings.

Shot blasting

Shot blasting is a technique consisting of projecting microbeads onto the surface of a part to modify its surface structure.

Goals can be:

- surface treatment to improve adhesion (similar to sandblasting)

- cleaning and stripping parts

Phosphating

Phosphating is a chemical reaction carried out using a phosphorus agent, more particularly the treatment of steel with phosphoric acid. The treatment of a steel surface by phosphating provides passivation and improves the corrosion resistance of paint coatings.

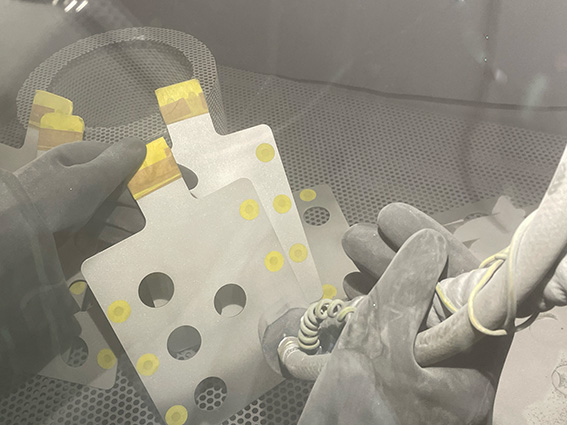

Masking

Masking is an important step before the surface treatment operation. It consists of positioning adhesive tapes or covers. A paper and/or high performance adhesive tape or an elastomer cover is thus applied to the areas to be spared. Many metal or elastomer tools can also be used depending on the shape of the parts and the areas to be masked.

To be noted: APS designs and develops its own masking solutions.

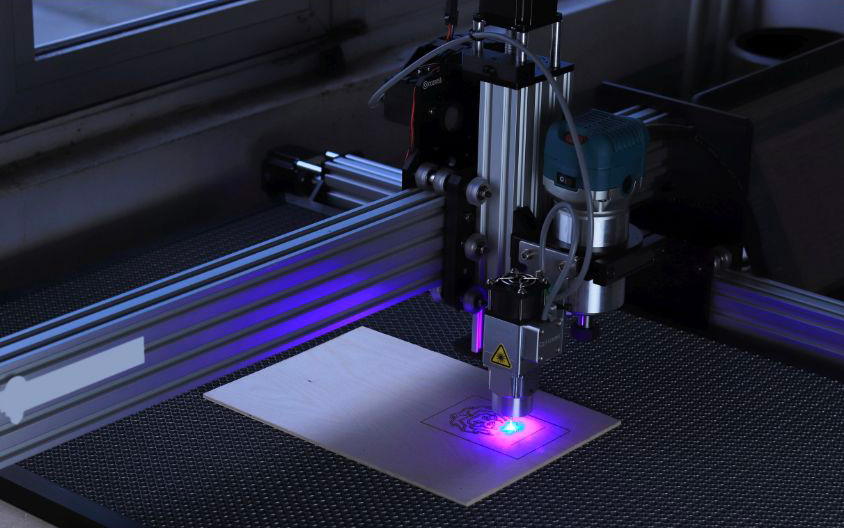

Laser surface preparation

Laser surface preparation is a technique under development at APS Coatings. Ultimately, it should allow:

- to eliminate pollutants (greases, oils, oxides, dust, etc.) and obtain an ideal surface condition and roughness to maximize the adhesion and performance of coatings.

- to strip a coating already applied to certain areas of the part in order to save money without resorting to masking these areas.