CVD

Chemical vapor deposition (CVD) coatings use thermal processes that activate chemical reactions, all of which is carried out in a vacuum chamber.

The principles of CVD

Our process implemented for the production of parylene is a CVD type deposition. Therefore, it has the particularity of having a hot phase far from where the parts are located, a technique known as remote CVD. This feature allows us to treat all types of parts, especially those that are thermally sensitive because, throughout the process, they will remain at a temperature close to ambient.

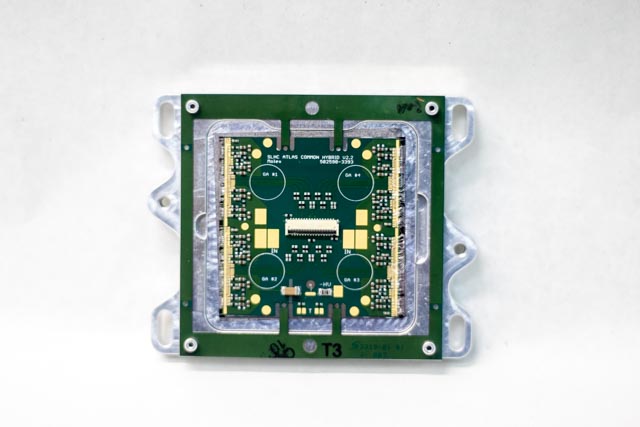

Parylene is a high-tech film which is deposited by condensation, under vacuum, after sublimation and transformation of its precursor. It offers conformity and uniformity properties due to its composition and application process. There are different types of parylenes applicable to technical components of small dimensions. Its properties make it particularly sought after as a protective layer for elements sensitive to their environment. Finally, its dielectric properties make it a very common material in electrical insulation applications. Thus, parylene is used in various industries such as microelectronics, medical, micromechanics, defence, micro and nanotechnologies, etc.

- Precisely configurable thickness: from 500 nm to 100 microns

- Application temperature: below 40°C

The benefits of CVD

- Completely uniform, no holes

- Can be deposited on thermally sensitive materials such as silicones and elastomers

- Coatings of complex parts