Ecological transition

Faced with the new economic, societal and environmental challenges affecting the industry today, APS is changing to ensure the development of a more sustainable and environmentally friendly industry.

Sustainable development at the heart of our strategy

APS has always sought the most environmentally friendly technical solutions: elimination of harmful solvents, reprocessing of effluents, recycling of waste, optimization of resources are at the heart of our approach.

Our teams are made aware and trained in continuous quality methods, sustainable development issues and respect for the environment.

Eco-responsible formulas

The company has always been committed to developing solutions that respect the environment. As early as 1975, APS had solutions meeting the current criteria of European regulations. Indeed, APS is a pioneer in the field of zinc flake-based coatings, and has been using products free of Chromium 6 and heavy metals for more than 20 years.

We also anticipate market regulatory changes and always seek to develop formulas that respect the environment and human health. Thus, in 2014, we created Nuflon UHX, a high-performance non-stick coating without chromic acid or nMP, materials now regulated in Europe and presenting risks to human health.

Refilling to optimize resources

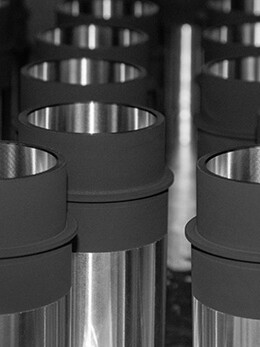

As part of the optimization of resources and the recovery of sometimes rare metallic materials, APS has been interested for several years in solutions for repairing parts. Many technologies such as additive manufacturing or thermal spraying techniques are being studied to repair certain parts, in particular wear parts or aeronautical parts, new with defects or worn.

The protection of People and the Planet

APS invests in processes to capture solvents and other volatile organic compounds to ensure the protection of its employees and the environment at all stages of production. We provide suitable equipment and we train our staff.

We have also been involved in the recycling of our waste for many years: reprocessing of corundum, treatment of effluent from the dip-spin line, recycling of cans of paint and other chemical products, selective sorting.

As part of reducing emissions and air pollution, we also have carbon filters at all our sites.

We are also investing in a fleet of hybrid vehicles for our employees aiming at going all-electric as soon as possible. The car parks at our two sites are already equipped with electrical terminals.

How can we help?

Do not hesitate to contact us for any quote request, we will answer within 24 hours.