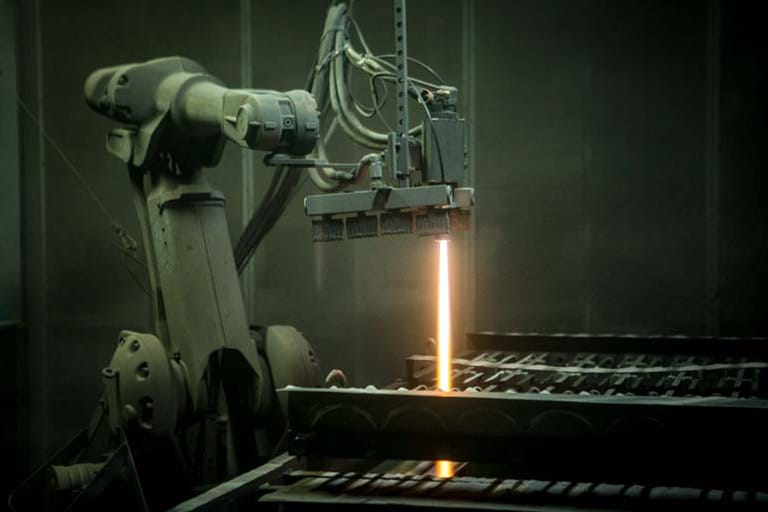

HVOF

The HVOF (High Velocity Oxygen Fuel) process is mainly intended for the supersonic projection of tungsten and chromium carbides, stellites, metals and their alloys.

The principles of HVOF projection

The HVOF process is based on the principle of a rapid flame, making it possible to produce metal coatings and their alloys (carbides, etc.) with good adhesion and better density (<at 1%) compared to other processes. It constitutes an improvement of the projection with the blowtorch (flame) by the use of the principle of rocket engines, which generates a flame characterized by a very important speed of ejection of gas.

The filler material is generally in powder form and the process is mainly intended for the supersonic projection of specific carbides, metals or alloys.

The high speed of the particles, the uniform heating and the short residence time in the flame generate the formation of a coating with high adhesion, high density and low oxidation.

- Heat source: fuel oil (liquid) and oxygen

- Materials: metal powder and metal carbides

- Flame temperature: 2,800°C (approx.)

- Particle speed: 400 – 800 m/s

- Deposition rate: 4-12 kg/h

The principles of HVOF projection

- Protection provided by a thick and dense coating

- Extreme compactness (less than 1% porosity)

- Low oxidation compared to plasma and electric arc

Possible features

Resistance to oxidation and corrosion

Electrical conductor

Resistance to impact erosion

Resistance to wear, friction

Resistance to oxidation/sulfidation

Increase in surface hardness

Sustainable HVOF solutions

Alternatives to hard chrome plating

In recent years, chrome plating has been questioned since this surface treatment process emits a substance considered carcinogenic. Carried in air and drinking water, this substance is highly dangerous.

In order to overcome this problem, regulators have implemented stricter air quality standards as part of the chrome plating process. APS did not wait for this regulation to be created to develop solutions that are more respectful of people and the environment.

HVOF coatings have proven to be vastly superior to chrome plating in terms of wear resistance (up to 5 times more effective) and provide equal or better protection against corrosion.

Unlike hard chrome plating, HVOF spraying has many materials to choose from depending on the application. Certain ceramic materials tested at APS Coatings gave results comparable to hard chrome plating.

Interested to know more?

Do not hesitate to contact our innovation department to find out more about HVOF spraying solutions as an alternative to hard chrome plating.